E-Mobility

Home » Applications » E-Mobility »

Related Products

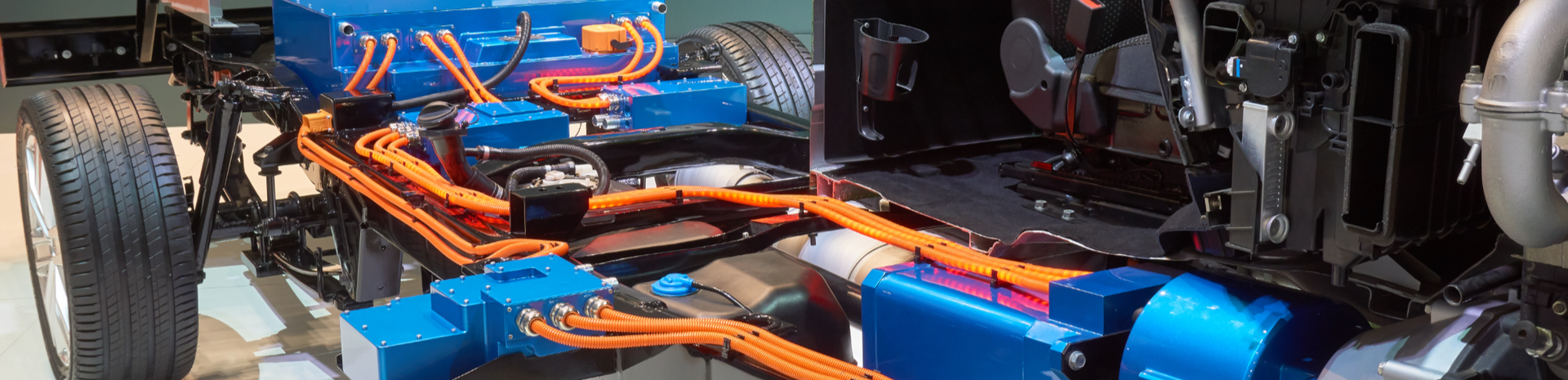

E-Mobility

Electric vehicles have existed for more than 100 years, with lead-acid batteries. But today, the li-Ion battery dominates the automotive engineering mind.

High energy density, lightweight, safe, low self-discharge and fast recharge characteristics of Li-ion battery packs make them a clear choice as the stored energy power source for electric vehicles, hybrid or plug-in hybrid electric vehicles.

HBL’s battery engineering experience ensures the right choice as each vehicle battery is engineered individually.

Typically, an EV battery consists of individual Li-ion cells that are connected in series and multiple parallel modules in order to achieve the required power and energy. However, the real complexity of optimal use of the battery is in the system integration of high-voltage components – especially matching the battery with the drivetrain and charging system.

HBL designs and builds the three main components of an electric vehicle – the drive motor, motor controller, and battery modules. This ensures seamless integration between people that control the technology. Backed with its strong experience of researching, designing, and developing battery technologies for mission-critical applications, HBL provides effective, affordable vehicle electrification solutions using Li-ion batteries.

HBL designs powertrain systems including the battery, charging system, motors, and controllers for this fast-growing market.

Please visit www.hblelectronics.com / http://www.hblelectronics.com/e-Mobility-Drive-Train.html for more information.